+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

Notícias de tecnologia

Casa >> Blog >> Notícias de tecnologia

With the accelerated development of China's industrialization process, industrial production and market demand are also increasing year by year. Ordinary metal processing equipment has been unable to meet the needs of industrial mass production. Processing companies are also increasing their requirements for improving production efficiency and reducing production costs. Laser equipment used for cutting metal workpieces has attracted more and more attention from enterprises and is also being used in more and more industries.

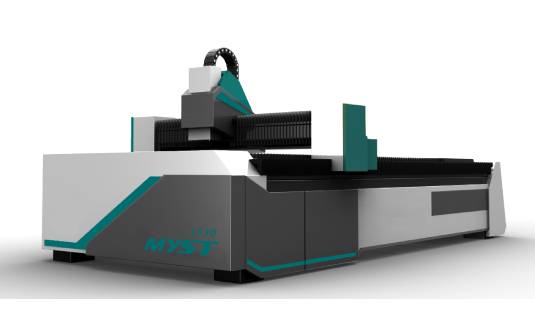

Fiber Laser Marking Machine

Generally speaking, the most common laser cutting machine on the market is Fiber Laser Marking Machine. Fiber laser cutting machine is one of the main tools for sheet metal processing. Compared with traditional sheet metal processing methods, it is not only technical Innovation is a breakthrough in processing efficiency and quality. It is mainly used for cutting carbon steel plates within 20mm, stainless steel plates within 10mm and other metal materials. It is mainly used in industries such as machinery manufacturing, automobile industry, oil mining, metal processing and so on.

The fiber laser cutting machine has greatly improved the accuracy and speed compared with traditional equipment. Its cutting slit is small and is not restricted by the shape. It is a non-contact cutting method. The cutting end is smooth and free of burrs and few deformations. Low cost, energy-saving, and environmental protection.

Professional Laser Marking Machine

The selection of a professional laser marking machine must consider many factors. First, stable performance is an important measure of equipment, and it is also the basis for purchasing equipment. Second, the maximum size, material, and maximum thickness to be cut and the size of the raw material format must be taken into account for the cutting accuracy, speed and heat-affected zone.

With the continuous improvement of the cutting technology, the fiber laser cutting machine gradually replaces the traditional processing methods and becomes a new trend in the application of the metal cutting industry. With the ever-expanding range of applications, I believe that the future market demand for fiber laser cutting machines will be greater and greater.

Análise dos fatores que afetam a qualidade do corte a laser e como controlá-lo

Comparado com o método de corte tradicional, o corte a laser tem as caracterí...

Campos de aplicação da máquina de corte a laser de fibra

As máquinas de corte a laser de fibra estão gradualmente se tornando populare...

Como fazer a manutenção de uma máquina de corte a laser de fibra

Os donos da loja de fabricação de metal têm muitas coisas à mão. Esses ge...

+8613256742787

Adicionar: Sala 2309, Builing 3, Bloco Lvdi Ruili, distrito de Shizhong, cidade de Jinan, província de Shandong, China.