+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

Notícias de tecnologia

Casa >> Blog >> Notícias de tecnologia

In today's commercial information age, consumers can learn a lot of useful product information through the Internet, and they can also query the industry rankings of CNC laser metal cutter manufacturers through the Internet, which greatly reduces the situation that consumers are deceived because of information asymmetry. With the development of the times, when consumers buy high-tech products such as laser CNC metal cutting machines, they will conduct strict comparisons in terms of product quality, product prices, after-sales service, etc, and their buying behavior is becoming more and more rational.

The emergence of a 1kw laser cutting machine has greatly reduced the labor cost in the production process. In order to improve the production efficiency of the factory and save labor costs, many companies have begun to focus on the 1000w fiber laser cutting machine. At present, there are many best metal laser cutting machine manufacturers on the market. For ordinary consumers who have no experience in purchasing raycus fiber laser cutting machines, it is not enough to simply screen suppliers through network information. What are the factors to judge a good cutting machine for metal sheet supplier?

sheet and pipe laser cutting machine

1. Product quality

Product quality is the most direct factor that reflects the quality of the manufacturer. Metal laser cutters have high requirements for quality, and the performance of equipment produced from different raw materials will vary greatly. Therefore, when choosing each part of the machine, manufacturers must do strict quality control. Laser cutting machine for metal manufacturers choose Well-known brand accessories and non-influential brand accessories will seriously affect the performance of the whole machine. The performance of the same type of stainless steel laser cutting machine is also very different. The configuration of the machine will have a great impact on processing quality. Choosing the configuration and functions that suit you can reduce procurement costs. Don't cause the machine to malfunction in the subsequent production process because of the selection of an accessory.

part of the metal fiber laser cutting machine

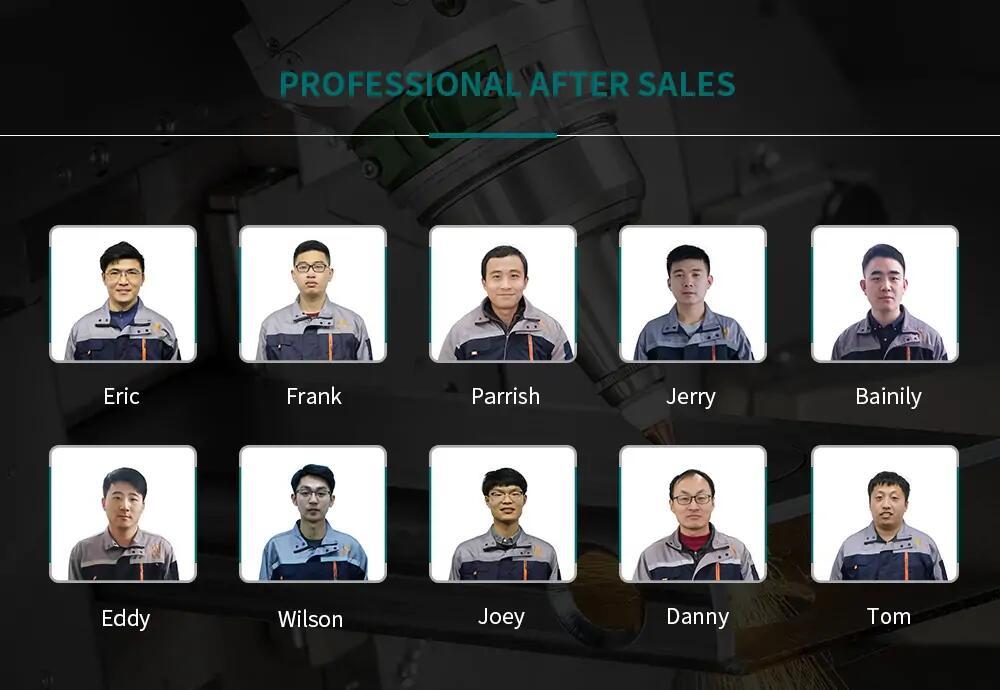

2. After-sales service

A formal CNC laser cutting machine metal manufacturer will have a professional after-sales service team. Choose manufacturers with good after-sales service. Each manufacturer's after-sales service is very different, and the warranty period is also uneven. In the after-sales service, it is necessary to provide customers with daily maintenance programs. For machines and laser software, there must be corresponding training systems to help customers get started as soon as possible. Moreover, no matter how good the quality of the ss laser cutting machine is, users will encounter problems during use. When manufacturers encounter problems that customers cannot solve by themselves, it is very important whether the manufacturers can provide solutions in time. This is also an important factor that consumers need to consider when buying a stainless laser cutting machine.

fiber laser cutting machine after-sales team

3.The price of CNC laser cutting machine steel

Looking at the official website of well-known manufacturers of flatbed laser cutting machine industry, we can find that the price range of the same type of laser cut metal plate machine is almost the same. During the inquiry process, the price range of the manufacturer is not much different. If it is an informal cheap metal laser cutting machine manufacturer when the customer asks for the price, the other party will not give a fixed price, and the bargaining range is relatively large. Through the accumulation of experience in daily life, we also understand the principle that you get what you pay for. The price of iron laser cutting machines from good manufacturers will be slightly higher, but the product quality and after-sales service are guaranteed. The price of some unknown manufacturers is cheap because they cut corners in the production process, the product quality is not guaranteed, and they do not provide corresponding after-sales service.

Sheet and tube metal laser cutting machine

4 Factory scale

If conditions permit, consumers can take a look at the factory's factory scale and the production workshop of the CNC laser metal cutting machine, specifically look at the workshop's operation process, the precision of the assembly of the workers, the brand of parts, the working atmosphere of the workers, etc. . These are all important factors to judge whether a manufacturer is good or bad. The factory with large scale, many machines, and precision parts processing are worthy of customers' trust. Some small workshop-type manufacturers do not have their own factories. They will steal the video of the workshops released by large-scale manufacturers to deceive consumers. Therefore, if conditions permit, try to go to the manufacturers' factories for on-site inspections.

fiber metal cutting machine factory interior

5. Word of mouth and popularity

The reputation of the manufacturer reflects the level of consumer recognition. The metal laser cutter produced by the manufacturer with a good reputation is of better quality and can better meet the needs of customers in all aspects. Consumers can search for 500w laser cutter manufacturers on the Internet and make choices by observing their reputation and popularity.

customer visiting

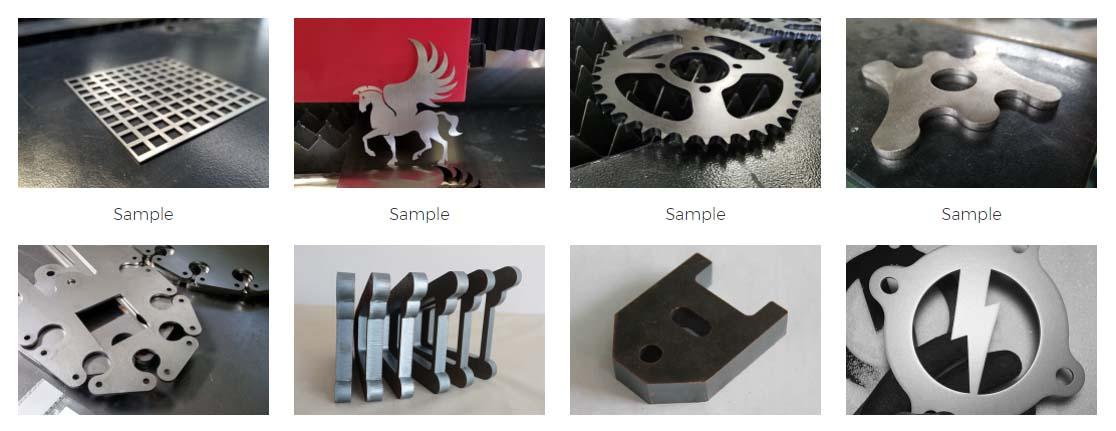

Since the advent of the metal laser cutting machine, the factory workshop operators have been replaced by the ipg laser cutting machine. Unlike ordinary metal forming equipment, it does not need to be equipped with manual assistance. The 1000w laser cutter has been matched with related functions when it is set at the factory, and can automatically complete a series of processing processes. Technically speaking, the fiber laser cutting machine makes the entire mechanical processing closer to precision processing, cutting patterns are becoming more and more complex, and processing materials are becoming more and more extensive. The sheet metal laser cutter solves the problem of high labor costs for enterprises, and at the same time improves the processing quality of enterprises.

cutting sample of fiber laser cutter machine

For manufacturers, if they want to achieve long-term development, maintaining professionalism is essential. On this basis, manufacturers must also have the ability to innovate and continue to innovate to inject new vigor and vitality into the enterprise. This is also an important guarantee for affordable fiber laser cutter manufacturers to maintain their professionalism. Only by constantly innovating can manufacturers break the original technical barriers, and the machines they produce can meet the needs of consumers to a greater extent.

Since MYST Laser was established in 2004, the optical fiber laser cutting machine produced is exported to more than 120 countries in the world. We have 16 years of experience in the production of the steel laser cutter. Every machine sold has undergone a strict quality inspection. We have a professional after-sales team. If customers encounter any problems in the process of using the steel laser cutter, our after-sales personnel will provide solutions in time. If necessary, we have professional after-sales personnel to provide on-site service MYST Laser’s plant covers an area of 32,000 square meters. The CNC laser metal cutter produced is reasonably priced, reliable in quality, and highly recognized by customers. Customers who place orders at our factory often place orders again.

CNC fiber laser cutting machine factory

When customers choose laser cutting fiber machines, they should choose manufacturers with good reputations as much as possible. If conditions permit, they should go to the field as much as possible to have a more intuitive experience of the cutting quality of the machine through on-site testing. There are many manufacturers of metal laser cutting machine on the market, and the one that suits you is the best.