+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

Notícias da empresa

Casa >> Blog >> Notícias da empresa

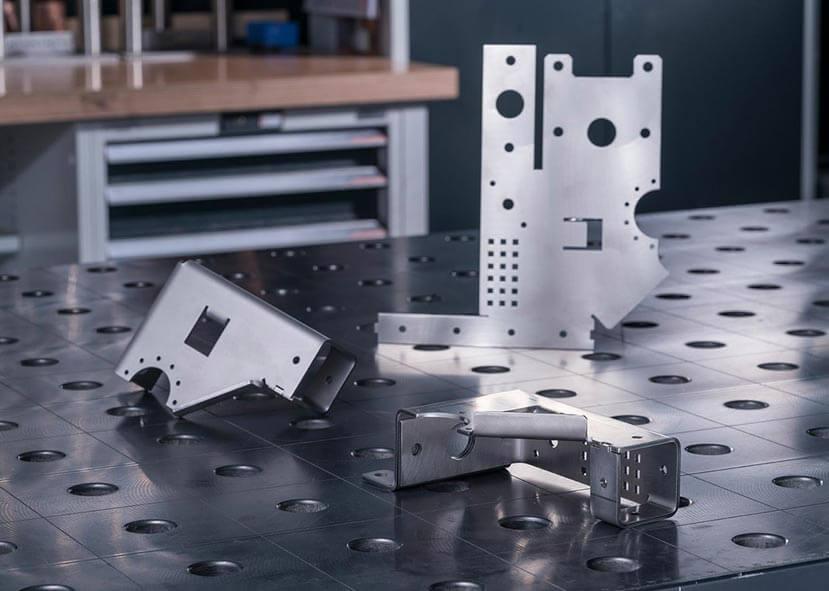

The sheet metal processing industry is one of the most important application markets for laser equipment. In recent years, the sheet metal processing industry has developed vigorously, and the competition for metal processing equipment has also intensified. The market demand for high-quality and high-tech equipment is also increasing. The appearance of the CNC fiber laser cutter just filled the vacancy of high-tech products in the market and occupied an unshakable position in the sheet metal processing market at the beginning of its appearance. More and more people see the value of desktop fiber laser cutter. What makes CNC laser steel cutting machines so popular? MYST Laser takes you to find out.

sheet-metal working

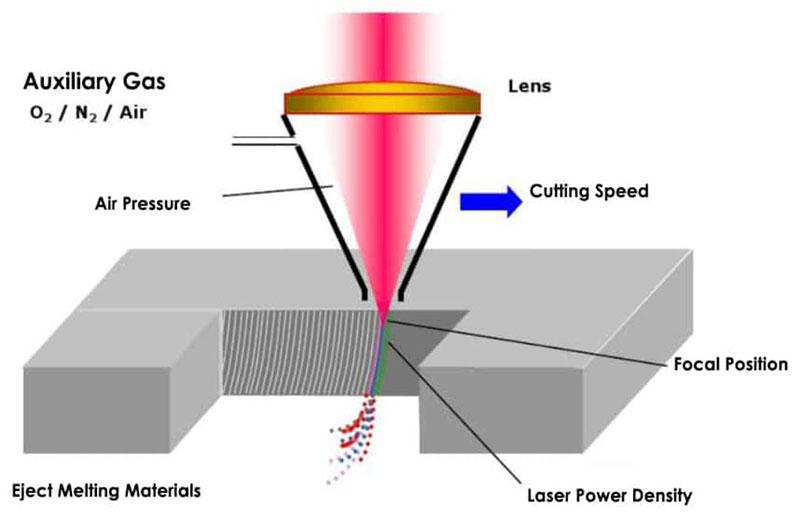

CNC fiber laser cutting machine is a new type of laser cutting equipment. Its working principle is that a high-energy laser beam irradiates the surface of the workpiece to make the workpiece reach the melting point or boiling point, while the high-pressure gas blows away the molten or vaporized metal. As the relative position of the beam and the workpiece moves, the material will eventually form a slit, so as to achieve the purpose of cutting.

fiber optic laser cutter working principle

Laser cutting is currently the most advanced cutting technology in the world. Most metal processing uses fiber optic laser cutting machines, which are also metal processing equipment. How strengths are desktop fiber laser cutting machines to stand out among many equipments? What are the characteristics of laser fiber cutting?

The cutting quality is good: non-contact cutting, the heat-affected area of the cutting seam is small, and the cutting seam generally does not require secondary processing. The laser is less affected by the environment, can achieve high energy output in a short time, and has a small laser spot. High energy density, good cutting effect. The heat-affected area of laser cutting is very small, the cutting seam is between 0.1-0.2mm, and the cutting seam section is a regular rectangle with a beautiful shape. The cutting surface of laser cutting is smooth and burr-free, and the cut parts can be used directly without reprocessing. It can be used as the last process of sheet metal processing.

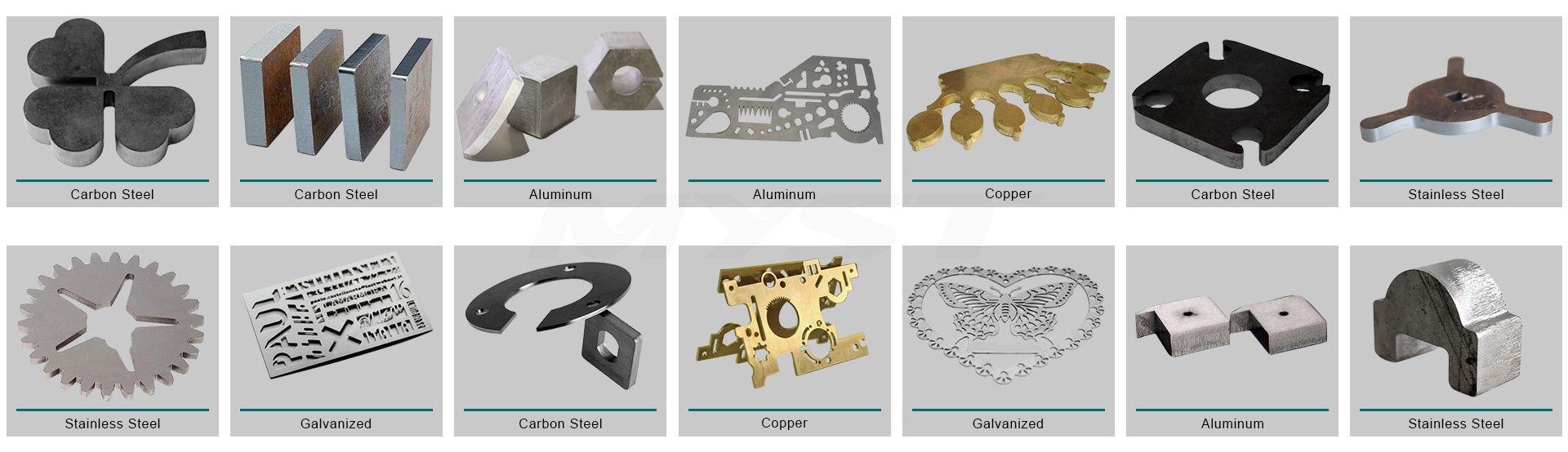

fiber laser metal cutting machine cutting sample

2.Fast cutting speed: The laser cutting speed is fast. The 1000 watt laser cutter can cut carbon steel plates below 2mm, and the cutting speed can reach 8 meters per minute. The deformation of the workpiece is extremely small during the processing, and no tools are needed to fix the workpiece, which saves the time of clamping the workpiece and makes the cutting speed faster.

3. A wide range of cutting materials: ipg laser cutting machine can cut stainless steel, carbon steel, aluminum, copper, galvanized sheet, and other metal materials, and can also cut plastic, wood, rubber, leather, ceramics. For non-metallic materials such as paper products, the performance of laser cutting will vary due to the different absorption rates of different materials.

4. High cutting accuracy: The positioning accuracy of the laser cutting machine for metal sheet is 0.05mm, and the repeat positioning accuracy is 0.02mm.

5. Little environmental impact: The laser beam of the custom metal laser cutting machine is different from the electron beam. The laser processing is not interfered with by the electromagnetic field and does not need to create a vacuum environment.

6. Suitable for processing large workpieces: the mold manufacturing cost of large workpieces is high, and the laser cutting steel plate machine does not require a mold during the cutting process, saving processing costs.

7. Safety and environmental protection: The laser cutting steel sheet machine has low noise during the working process and hardly produces pollutants. It will not harm the health of the staff and will not affect the processing environment.

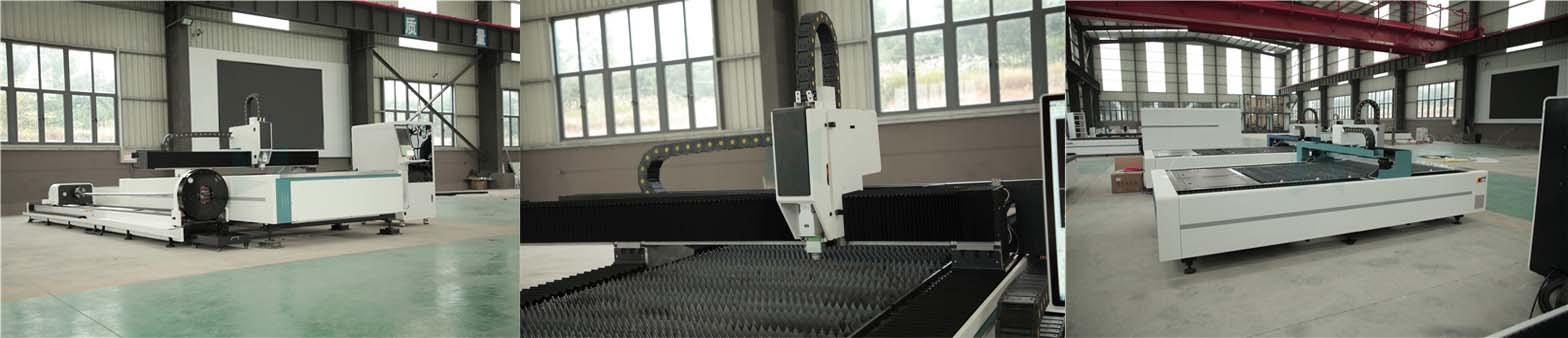

fiber cutting laser machine

With the continuous development of science and technology, there is more and more equipment available for sheet metal cutting on the market. In addition to the most popular desktop laser cutter for metal introduced in the article in recent years, there are also CO2 laser cutting machines, plasma laser cutting machines, YAG laser cutting machine, CNC router, water cutter, and wire EDM, etc. Among all kinds of cutting equipment, why can laser metal cutters stand out? What are the advantages and disadvantages of other cutting equipment?

CO2 laser cutting machine: Compared with CNC steel laser cutters, 2000w 3000w 4000W high-power CO2 laser cutting machines have high prices, many after-sales problems, and high maintenance costs. They have been eliminated by society. 200W 300W low-power CO2 laser cutting machine is mainly used for engraving and cutting of non-metallic materials, such as wood MDF (density board) acrylic and other materials. Its advantage is that it is cheap and can occasionally cut thin metals, such as carbon steel and stainless steel within 2mm, but cannot be processed in batches.. The CO2 laser cutting machine cannot process highly reflective materials, such as copper-aluminum galvanized sheets.

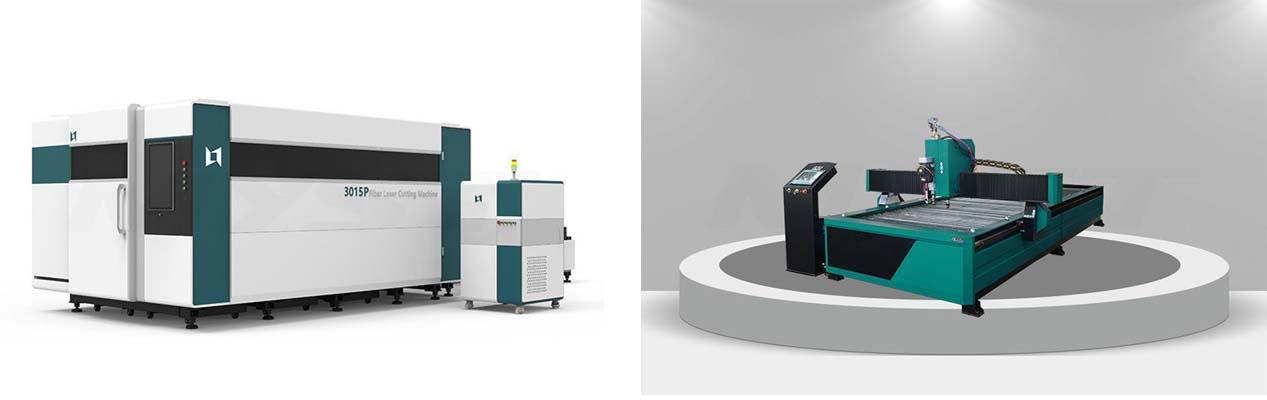

metal laser cutter and plasma cutting machine

2. Plasma laser cutting machine: Plasma arc cutting is a processing method that uses the heat of the high-temperature plasma arc to locally melt (and evaporate) the metal at the incision of the workpiece, and use the momentum of the high-speed plasma to remove the molten metal to form an incision. Compared to traditional flame cutting. Plasma cutting has greatly improved the cutting speed and cutting accuracy. However, compared with sheet metal for laser cutting, plasma cutting has a larger thermal deformation area when cutting thin steel plates, a larger slope, low cutting accuracy, expensive consumables, and high operating costs.

3.YAG laser cutting machine: Compared with laser iron cutting machines, YAG laser cutting machines are relatively inexpensive and can cut metals in batches. The disadvantages are low processing accuracy, high power consumption during processing, troublesome parts replacement, high maintenance costs, and low cutting power. It can only cut thin plates below 8mm, and the cutting efficiency is low.

4.cnc router: It is mainly used for carving and cutting of stone, wood, soft metals (copper, aluminum, etc.). Compared with the desktop metal laser cutter, the cutting surface is not smooth and has burrs. It cannot cut high hardness materials such as stainless steel and carbon steel.

5.Water cutter: It is a machine that uses high-pressure water to cut. It can sculpt the workpiece at will under the control of the computer. Compared with the 3d metal cutter, the price is cheaper. However, cutting materials are restricted, and materials that are afraid of contact with water such as paper and cloth cannot be cut. Compared with hobby laser cutter metal, cutting accuracy and cutting speed is lower.

fiber laser cut stainless steel tube 2mm

Metal cutting laser CNC machine is a technological revolution in sheet metal processing, and it is a rising star in sheet metal cutting equipment. Cutting metal laser has a high degree of flexibility, fast cutting speed, high production efficiency, and short product production cycle, which has won a wide range of markets for customers. Cutting laser metal has no cutting force, no deformation in processing; no tool wear, good material adaptability; no matter simple or complex parts, you can use the laser to cut precisely and quickly at one time; it has narrow slits, good cutting quality, and a high degree of automation. The operation is simple, the labor intensity is low, and there is no pollution; automatic cutting and nesting can be realized, the material utilization rate is improved, the production cost is low, and the economic benefit is good. The effective life cycle of metal sheet laser cutting is long. In the current sheet metal processing market, most of the plates that need to process more than 2 mm thick choose sheet metal laser cutters. Many industry experts agree that in the next 30 to 40 years, fiber cutting laser machine will enter a golden period of development.

laser pipe cutting machine

Fiber laser cutters are intelligent cutting equipment with excellent performance. In the field of sheet metal processing where competition is becoming more and more fierce, fiber optic laser machine has taken a place.

Nenhum