+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

+8613256742787

Máquina de corte a laser de metal, Máquina de corte a laser de fibra, Fornecedor de máquinas de corte a laser, Máquina de marcação a laser, Máquina de marcação a laser de fibra...

Notícias da empresa

Casa >> Blog >> Notícias da empresa

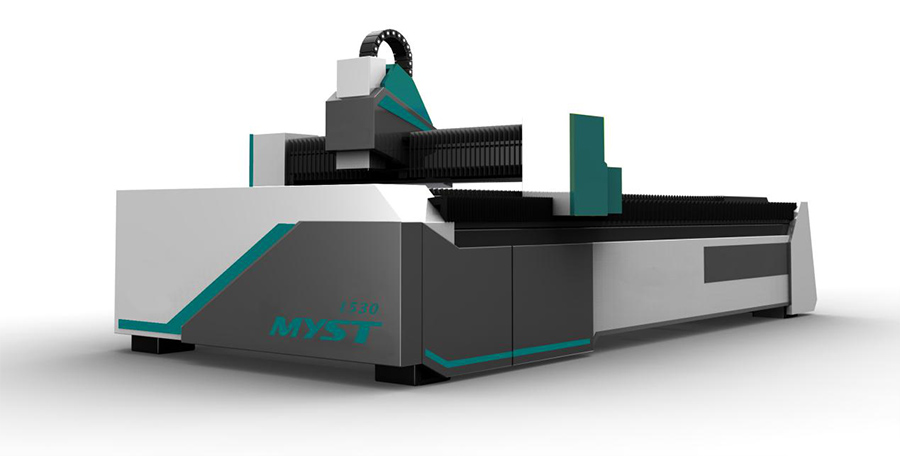

The CNC laser cutting machine has the characteristics of high-precision, high-efficiency, high-quality and high- integration. On the one hand, it benefits from the excellent characteristics of the laser, and can meet the different needs of users. For different types and specifications of products, it can realize a variety of plates, Pipe processing; on the other hand, it is also closely related to the design of its structure.

Myst Laser is committed to creating more efficient and convenient laser cutting equipment, so a more reasonable structural design is the direction we have been working hard. Below we will analyze the characteristics and requirements of the structure of the CNC laser cutting machine.

1. Gantry machine structure

At present, the structure of CNC cutting machine tools on the market mainly includes gantry type, cantilever type and cross beam type. Among them, the gantry type is easy to operate due to its open type, and can be combined with the high-performance numerical control system to realize the bilateral synchronous drive in the full sense, which has become the mainstream structure of the current CNC laser cutting machine. Myst Laser conforms to the development needs of laser equipment, and also adopts gantry machine structure. Our products are especially suitable for high-dynamic and high-precision.

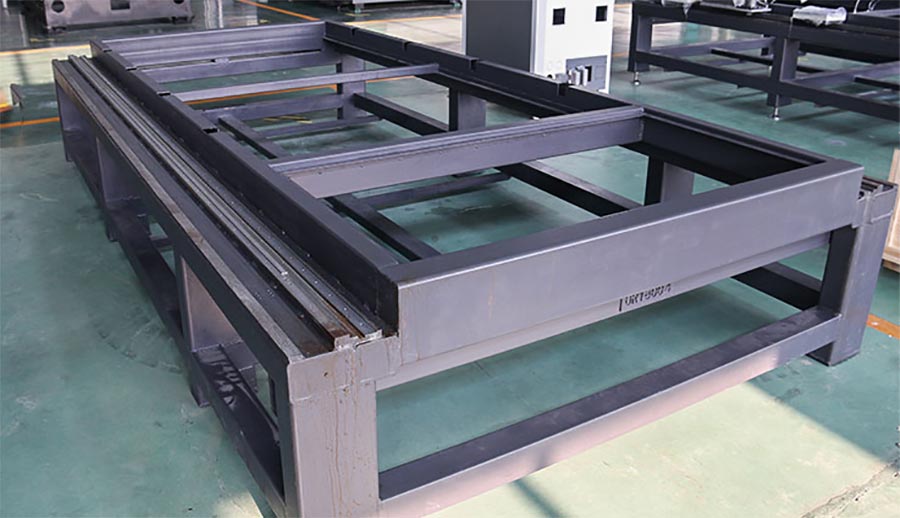

2. Machine tool base weighted design

In order to ensure the cutting efficiency and precision, the base part of the machine tool of CNC laser cutting machine usually adopts the weighting design. On the one hand, it can increase the loading capacity of the bed and improve the efficiency of one cutting. On the other hand, it can meet the force characteristics and can effectively avoid the vibration generated by the moving center of gravity of the workpiece,and also avoid the failure of the transmission and the guiding parts that is due to instant overload, makes the laser beam focus to remain stable.

3. Motion mechanism

The motion mechanism determines the performance of the cutting machine. Under the premise of stable body, the precise moving distance and angle are the factors that directly affect the cutting precision. The inertia ratio of the load is the primary consideration in the design of the motion mechanism. Compared with the general motor, we generally choose a motor with an inertia ratio of about 1:3, so that the machine tool drive parameters of the CNC laser cutting machine can reach the optimal state.

4. Follow-up mechanism

The part,used to detect and control whether the surface of the cutting workpiece is smooth when the cutting machine is running,is called the follow-up mechanism of the laser cutting machine. After the fiber laser source releasing the high energy density laser beam, the focus of the laser beam need to be focused on the surface of the workpiece before cutting, and the height of the focus (ie the height of the torch) is adjusted by the servo motor and the transmission. Since the position of the focus directly affects the cutting slit width and cutting quality to a certain extent, the requirements for the follower mechanism are high. The detection accuracy is required to be around 0.010mm. In combination with the above requirements, we generally control the follow-up speed to about 5m/min, which not only ensures that the torch does not vibrate up and down due to excessive moving speed, nor does it prevent the torch from catching up because the speed is too low.

CNC laser cutting machines are precision workpiece processing devices, so only products with more precision will be widely recognized. Myst Laser has always adhered to this belief and devoted itself to the production of more perfect products.

Análise dos fatores que afetam a qualidade do corte a laser e como controlá-lo

Comparado com o método de corte tradicional, o corte a laser tem as caracterí...

Campos de aplicação da máquina de corte a laser de fibra

As máquinas de corte a laser de fibra estão gradualmente se tornando populare...

Como fazer a manutenção de uma máquina de corte a laser de fibra

Os donos da loja de fabricação de metal têm muitas coisas à mão. Esses ge...

+8613256742787

Adicionar: Sala 2309, Builing 3, Bloco Lvdi Ruili, distrito de Shizhong, cidade de Jinan, província de Shandong, China.